Robust design

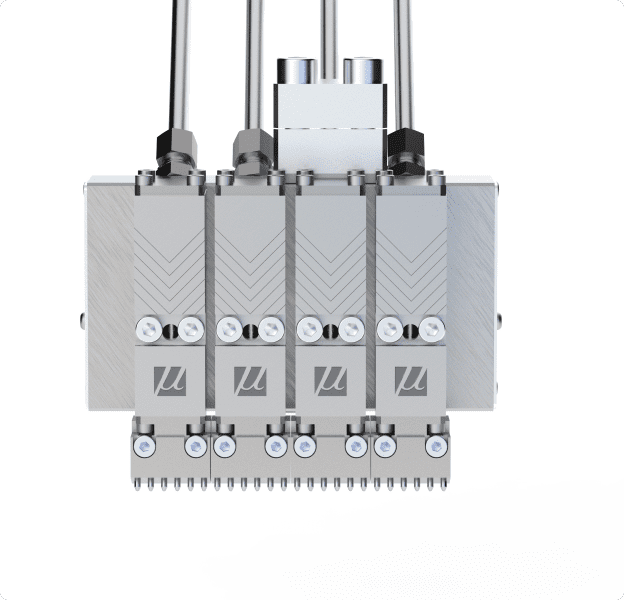

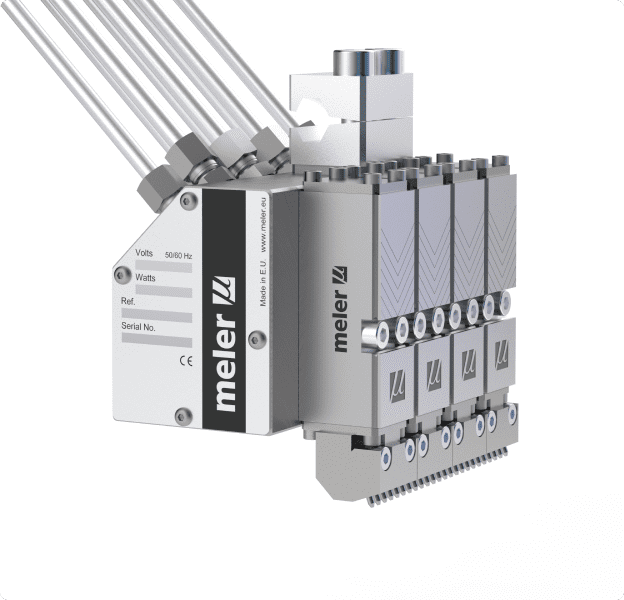

Based on MS.U or MD.U. applicator bodies.

High configurability

The nozzles can be interchanged between modules to achieve the pattern required for each application.

WHERE TECH MEETS MAGIC BENEFITS THAT CHANGE EVERYTHING

Specifications that change everything

- Options: single or double acting pneumatic opening/closing control (AOSC/AOAC)

- Different versions of nozzles:

- Vertical version (BMV): Triggering in the direction of the injector module.

- Vertical version at 20° (BMV-20°): Triggering at 20° in the direction of the injector module.

- Horizontal version (BMH): Firing perpendicular to the direction of the injector module.

TECHNICAL SPECIFICATIONS

- WORKING TEMPERATURE

Up to 230ºC (446ºF) - MAXIMUM WORKING PRESSURE

90 bar (1,305 psi) - BUILT-IN FILTERING

Standard 100 mesh (50 and 200 mesh available) - MAXIMUM PNEUMATIC PRESSURE

6 bar; dry, clean and unlubricated - WORKING SPEED (*)

Up to 8,500 dots/min - TEMPERATURE CONTROL

RTD ±0.5oC (±1°F) (Ni120 or Pt100) - SUPPLY VOLTAGE

230 VAC, 50Hz (from melter unit) - SOLENOID VALVE VOLTAGE

24 VDC

* Depends on the type of adhesive.

Characteristics

- Versatility

- Usability

- Speed of response

- Accessibility

Configurations of these applicators

Bottom flap closing on a vertical filling machine with several gluing stations with an output of 50-80 cartons per minute/line speed of 30-40 m/min and a minimum applicator duty cycle of 15 ms.

There’s a bit of magic in all science The supported modules are as follows

Ball-closing module with air-operated opening and spring closing. For multi-bead nozzles up to 6 lines.

MSU.MT module

Ball-closing module with air-operated opening and closing. For multi-bead nozzles up to 6 lines.